Collaborate, Create, and Learn–The MakerSpace

Aspiring poets, graphic artists, engineers, sculptors, computer scientists, entrepreneurs, environmentalists— it really doesn’t matter. The MakerSpace has something for everyone. All that’s needed is a little imagination and a willingness to learn new things. Throw in a pinch of patience, and you’ve got it made. Literally.

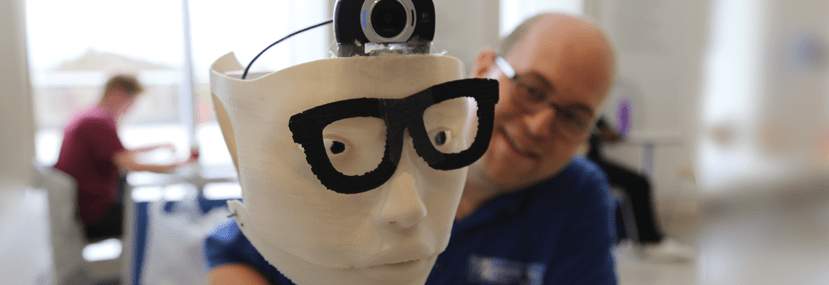

Simply said, The MakerSpace is a place where students, faculty, and staff can come together to collaborate, create, and learn. “It’s an interdisciplinary, cross-departmental space where students can dabble in robotics, design and print 3D models of human organs, and learn in Virtual Reality environments,” says John Mazzarella, manager of training, communications and marketing.

The idea to create The MakerSpace took shape in 2014 when Apurva Mehta, associate CIO, read a couple of articles in Educause, a nonprofit association whose mission is “to advance higher education through the use of information technology.”

Then, thanks to the efforts of a small grassroots committee whose members became intrigued with the idea of a space devoted to 3D printing and design, UMass Boston launched its own makerspace two years later.

Mehta, Mazzarella, and Filip Cuckov, assistant professor of engineering, were all there at the start. “The first order of business was to determine what kind of equipment we would need,” says Mazzarella. We were a little committee asking ourselves ‘How can we do this with very little funding.’ In addition to guidance from professionals from Brandeis University, which already had a makerspace up and running, the team sought help from their UMass Boston colleagues.

That’s when some fruitful collaborations took root. As it happened, the Engineering Department had its own small and sparsely equipped makerspace. Cuckov, however, agreed to move some of his equipment to the soon-to-be-established university makerspace in return for allowing engineering students access to the new facility. “This idea was a win-win,” said Cuckov. “The engineering department’s makerspace was limited to engineering students by virtue of its size and discipline-specific use. Moving to the larger space would allow more equipment to be added and more students to participate.”

Next, enter faculty from the Computer Science Department. Awarded a grant to buy VR equipment, they had nowhere to put it. The MakerSpace The MakerSpace answered the call, and yet another group of students gained access to the lab. Interest was growing by leaps and bounds.

“I’ve not seen so much excitement among so many people in a while,” says Mehta. “It was something quite novel on campus. The time and energy devoted to building the lab was tremendous.”

Not surprisingly, this all led to the openaccess policy, whereby The MakerSpace was available for use by all students, faculty, and staff free of charge—both for academic and personal projects.

Where to build the lab was a challenge. Helenmary Hotz, director of the School for the Environment’s Academic Lab, was next to provide a solution. Supported by her dean, she offered a lounge area in a former GIS lab, located in a building scheduled to be torn down.

“We were living in borrowed space and time, knowing very well that the building was to come down with no guarantee of being assigned space in another location,” says Mazzarella. “But our goal was to become so central to student learning that we would gain a vote of confidence from the university and be given a permanent home.”

Right on cue, the university acknowledged the lab’s success a few short months before the building was to be torn down and, happily, The MakerSpace was given an official new home in McCormack Hall.

The rest is history. The UMass Boston MakerSpace has proved worthy of the move and is utilized by faculty and students on a regular basis. Biochemistry Senior Lecturer Tara Ashok has assigned students the task of 3D printing human organs. Cuckov and students engineered a robotic arm with a promising future in the medical field. Mazzarella engaged Senior Alexander Travis to create hardware and software solutions to automate removing a 3D print job from the printer, increasing efficiencies by allowing several prints to be cued up and printed without human interaction. The MakerSpace has also begun hosting field trips for area high school classes to see the opportunities that will be available to them at a university makerspace. As anticipated … the possibilities are proving endless.